INTRODUCTION

Mass produced Batteries have now been around for more than 200 years, and until recently the rate of innovation was rather slow, however, in the last quarter century the massive increase in the desire for portable electronic equipment, and now equipment that is not only portable, but can provide it’s own motive power has lead

(-acid)

to a huge range of different options for battery powered products.

No one battery type provides answers to all the challenges design engineers have to overcome, in this post we would like to explain some of the characteristics and compromises that will inform the selection of battery for any type of product.

LEAD ACID BATTERIES

Lead Acid batteries have been around since time immemorial, and while they certainly have their limitations, the nature of this chemistry means that they lend themselves very well to certain applications, and lest we forget, you cannot get more bang for your buck.

Slide title

Write your caption here

Button

Perhaps the biggest drawback of all the various types of Lead Acid battery is their large size and weight, meaning they are not suitable for integration into portable products

(unless your target demographic happens to be Olympic weight lifters) Alternatively in products where ballast is considered a positive, a large lead acid battery definitely fulfils that need – meaning an installed product can be more stable in inclement weather and is less easy to remove without consent.

Lead Acid batteries are very robust in terms of their tolerance for temperature, and can withstand overcharging better than other chemistries (although every care should be taken to avoid overcharging any battery) they also have a very low self discharge level. This combination means Lead Acid batteries are ideal for low duty cycle, standby type applications – although there are ‘cylic’ models of lead acid batteries designed for more intense use, they are still limited to a few hundred full discharge/charge cycles before beginning to lose a significant amount of their stated capacity.

The other consideration is that, unsurprisingly, these batteries contain Lead so are not environmentally friendly in terms of manufacture or disposal at the end of their life. Many other heavy metals (see Cadmium) were removed from batteries by the RoHS directives. While these batteries are still the de-facto choice for starting combustion engines there seems little room for manoeuvre. As electric vehicles increase their market share pressure will increase for the restriction of the manufacture of Lead Acid batteries, with the resultant decrease in their universal availability and a potentially significant increase in cost.

We offer a full range of Lead Acid battery chargers

HERE

NICKEL BASED BATTERIES

Slide title

Write your caption here

Button

The first Nickel based batteries to achieve prominence were Nickel Cadmium chemistry, NiCd batteries have a number of extremely useful properties, they were happy with very high charge and discharge currents and could be stored for a long time and still used (once they had been ‘woken up’)

on the downside NiCd suffer badly from memory effect if not fully discharged regularly .

Also cadmium is a highly toxic metal, and following the RoHS directive NiCd batteries are now only allowed to be used in a limited range of approved applications.

Nickel Metal Hydride (NimH) batteries are much more environmentally friendly, and this is the default Nickel chemistry available for consumer and industrial batteries today. NimH batteries have been developed to have much higher capacity than the equivalent NiCd, and are available in a very wide range of standard case sizes from hundreds of manufacturers, meaning inter-operability is straightforward and cost to change is low. One of the most significant drawbacks of NimH batteries is their lack of thermal efficiency, high charge and discharge currents create a large amount of heat, potentially damaging the battery and reducing cycle and shelf life, combined with the fact that NimH has relatively high self discharge to start with, these batteries must be managed correctly in order to achieve their stated performance.

Haredata Electronics partner with a number of factories to provide a full range of

NimH battery packs

In addition FRIWO have developed a full

NimH/NiCd battery charger range with chemistry specific control algorithms to ensure Nickel based batteries maintain optimum performance!

LITHIUM ION BATTERIES

There are many types of lithium based batteries, all typically referred to by the material used for the Cathode in the battery – terms such as Cobalt Oxide and Manganese Oxide have been around since the 1990’s but there are now many more compounds that have been used for battery development, adding to the confusion some of these cathode materials can be mixed to give hybridised performance – perhaps the best known of these is Lithium Nickel Manganese Oxide (LiNiMnCoO2) also known as NMC, which combines the higher capacity of the cobalt based chemistry with the greater stability typical of the Manganese cells.

Slide title

Write your caption here

Button

All Lithium based batteries feature a common set of characteristics, they feature the highest energy densities – up to 250 Wh per Kg, and highest cycle life (up to 2,000 cycles) of all batteries, making them ideally suited for modern high drain consumer electronics.

However, as with most things in life there is a price to be paid for this superhero performance.

They are extremely susceptible to being damaged by overcharging or high rate discharge, in the worst case scenario this can lead to uncontrollable thermal runaway resulting in catastrophic failure.

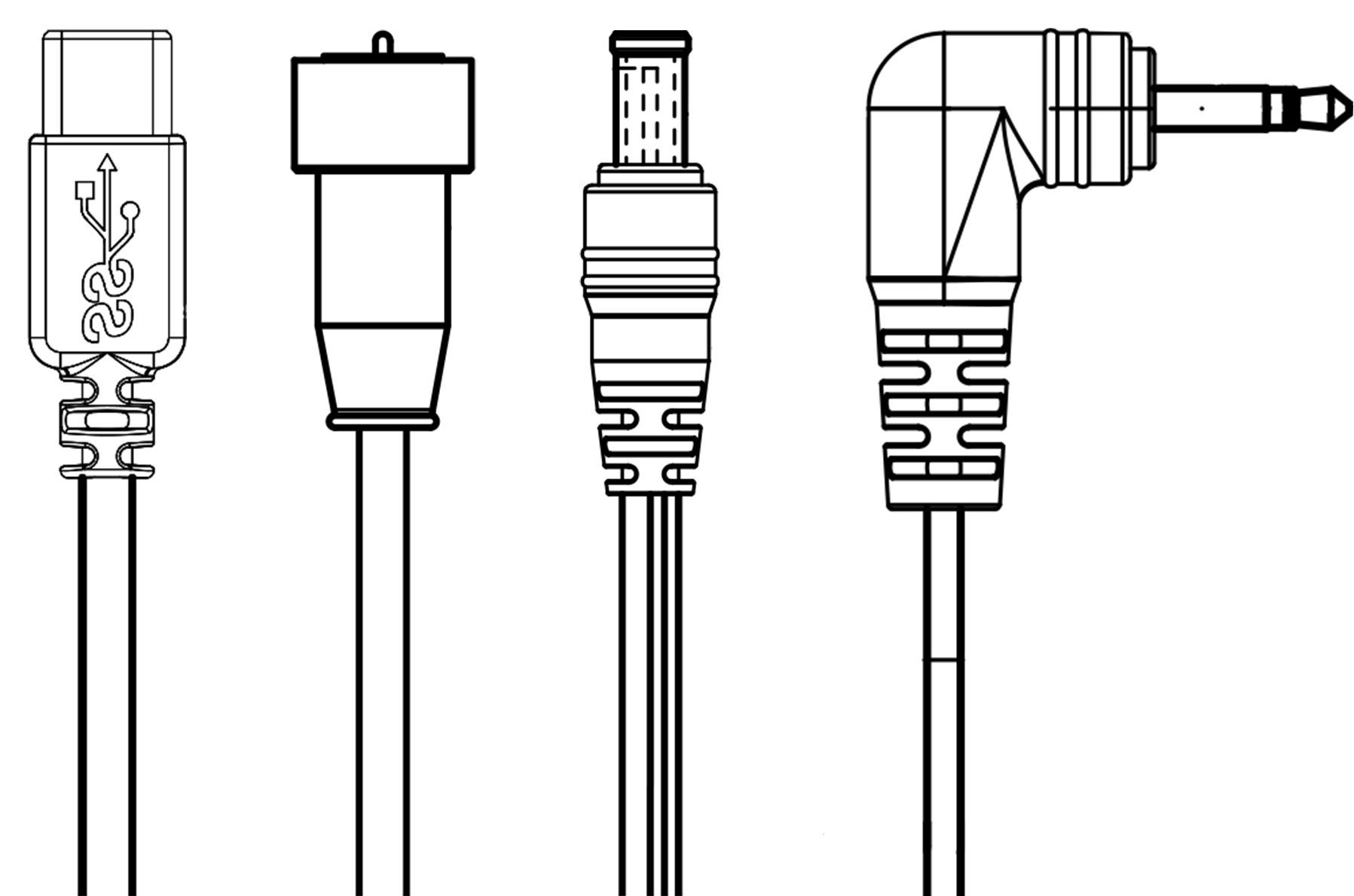

For these reasons it is a requirement for any battery pack composed of Lithium Ion cells to feature a Protection Control module (PCM) that, as a minimum, will prevent the battery operating outside defined safe parameters, many of these PCMs can include additional features such as voltage sensing and temperature monitoring that can then be reported via a communication protocol such as SMBus. This allows the equipment manufacturer to protect the battery and ensure it is only charged in accordance with the specification (or even only with the approved charger).

Slide title

Write your caption here

Button

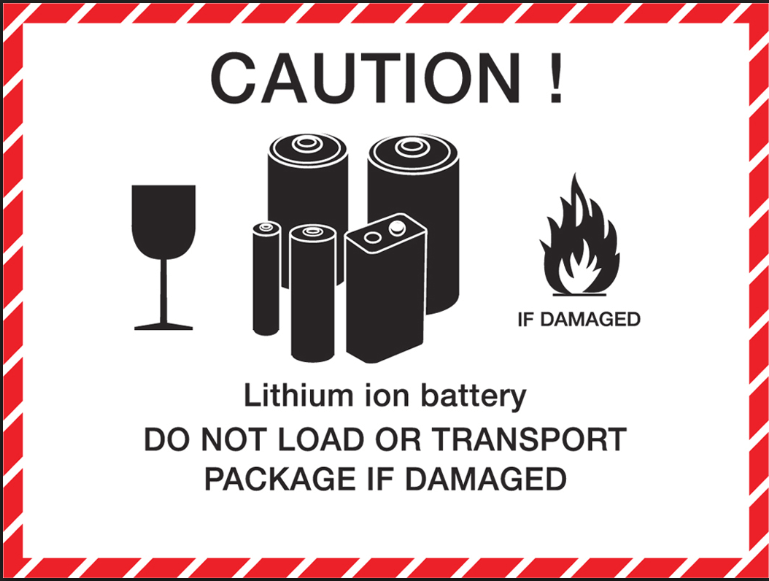

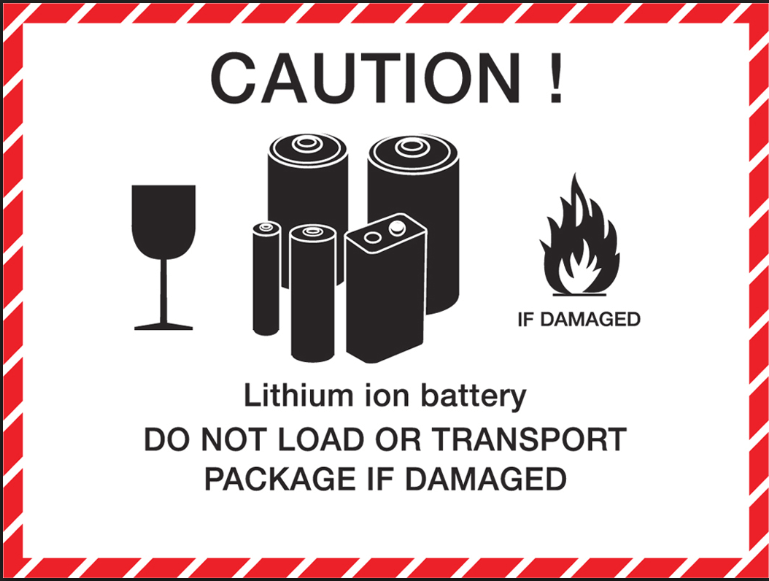

Additionally the shipment of Li-Ion battery packs is regulated,

UN38.3 specifies the required packaging and labelling requirements (example above), and it should not be assumed that compliance with this standard guarantees that every shipping company is happy to transport large quantities of Li-Ion cells, particularly via Air Freight. As a result the options for changing from one manufacturer of cell or pack to another, even if nominally of the same construction are limited, may require additional testing and approval and can take considerable time.

FRIWO have a wide range of

standard Li-Ion battery packs

in the most common configurations, they all feature UN38.3 and IEC62133 safety approval and have SMBus communication as an option. FRIWO also offer a sophisticated range of

dedicated Li-Ion chargers, designed to ensure safe charging of a wide range of Li-Ion battery packs, from 1 cell through to 10 in series, and with charge currents up to 4000mA.

BEFORE YOU GO!

We hope you found this BLOG useful, if you have any requirements or questions about batteries and their respective chargers...

Just get in touch and one of our expert will gladly assist you!